Relying on science and technology to form a characteristic forage production mode with competitive advantages, such as automation, low cost, all season, traceability, production on demand, safety and health

Visual rendering

Data transmission

Information mastery

Digital twins

Intelligent diagnostics

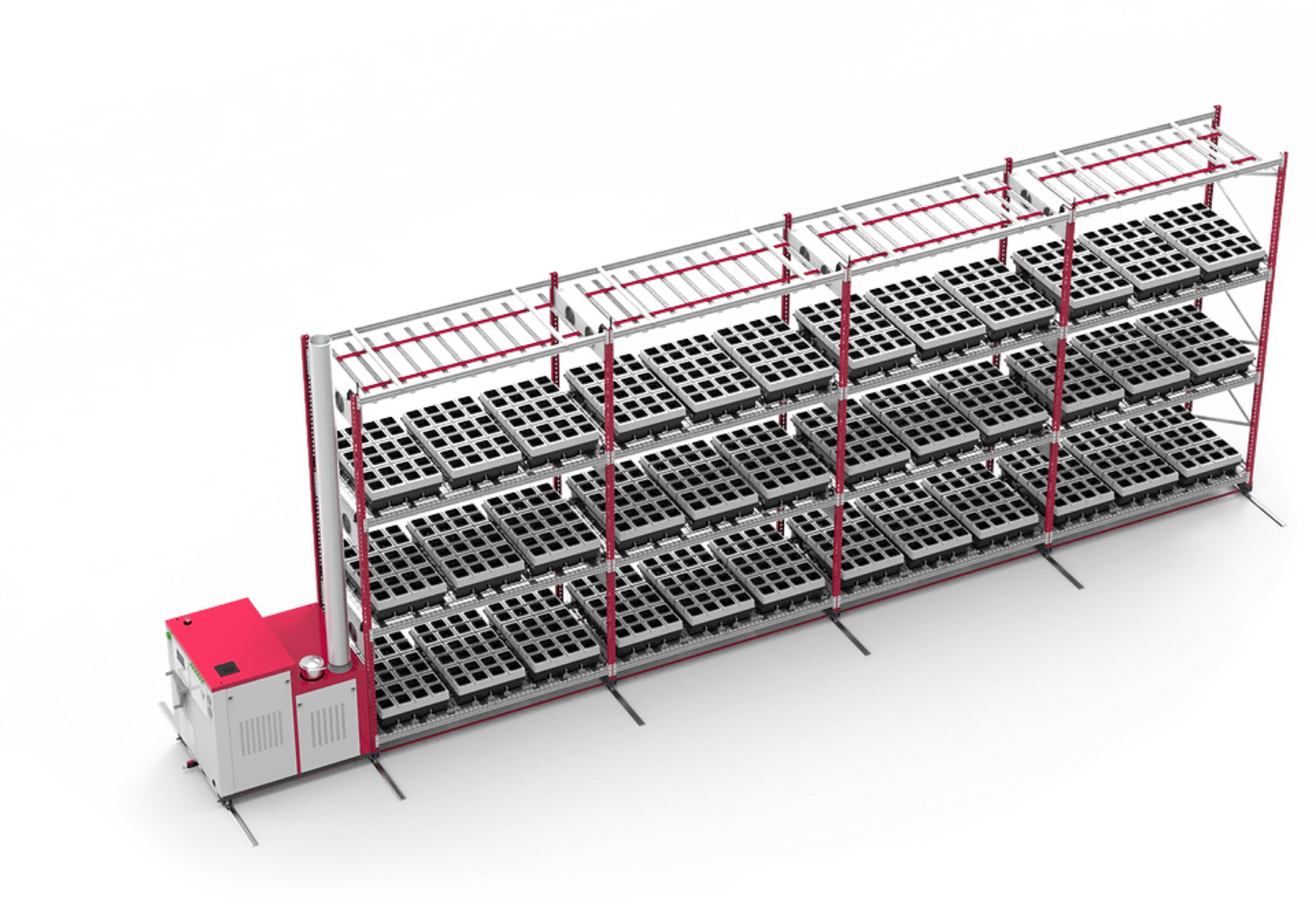

The forage cultivation system combines several growth modules (6, 12 or more GLS 808 modules) into a commercial scale indoor climate control environment, in which high-quality fresh water green feed crops can be grown automatically all year round.

Hydroponic feed is produced by planting seeds without soil and little water; In 6-7 days, seeds germinate, seedlings will be up to 30-35 cm, and provide highly nutritious feed.

General console

Air circulation system

Planting equipment

Automatic grass picking

Fully automatic tray laying

Ultrasonic wake-up seed

Programmed seed soaking

Zone temperature control system

Far infrared budding

Led programming band seedling

Automatic spray water replenishment

Water source recovery system

Wastewater filtration and discharge

The general console of the cultivation system is equipped with a large intelligent screen, which can intuitively let the cultivator know the situation of waking seed, germination and forage growth

The forage cultivation system consists of 13 parts, and each part has a separate console. However, on the general console, you can have a comprehensive view of the situation in the cultivation system and operate each control system with one key.

The indoor air is sucked into the machine from the return air outlet, purified by the air filter, and then enters the indoor heat exchanger (evaporator in refrigeration and condenser in heat pump heating) for heat exchange. After cooling or heating, it is sucked into the electric fan, and finally blown into the room from the air outlet.The function of the air circulation system is to force convective ventilation and promote the flow of cooling (heating) air in the room, so as to achieve the purpose of uniform cooling (heating) throughout the room. This can control the constant temperature and clean gas in the cultivation system to ensure the good growth of forage.

Forage planting equipment includes control system, lighting system, irrigation system, mobile planting rack and air flow system. The seeds after bud cultivation will be transported to the mobile planting rack for cultivation. In the growth stage, the irrigation system, lighting system and air flow system will be automatically adjusted with the growth of forage to ensure the optimization of forage growth environment.

After the wheat seeds are poured into the closing groove, the conveyor belt will automatically screen out quantitative seeds and evenly spread them in the waking seed tray. During the screening, empty shell seeds and bad seeds will be removed according to gravity induction to ensure the germination rate of seeds.

Ultrasonic seed awakening is to let seeds receive irradiation energy, effectively activate seed growth enzymes and awaken seed cell vitality, so as to enhance biochemical metabolism and promote growth. Soaking seeds correctly can not only affect the germination rate of seeds, but also achieve the purpose of increasing production.

In the process of seed soaking and germination, the equipment we use is composed of several parts. For example, temperature control mechanism, water tank, seed box, operation control mechanism, etc. After the seeds that have been automatically laid are transferred to the seed soaking box, it is operated through the control system to transfer the water with a certain temperature to the inside of the seed box through the temperature control system. The overall situation of seed soaking can be understood through the monitoring mechanism, and the whole process can be strictly controlled. In the process of production, programmed seed soaking can automatically soak seeds and promote germination. All processes are controlled by computer programming, which can maintain a certain temperature and water level, strictly control the time, and ensure the quality of production.

The most suitable growth temperature of wheat straw in each stage of growth is different. For example, the best temperature for seed soaking is 23 º C, the germination temperature is 8 ~ 16 º C, and the growth temperature of wheat straw is 16 ~ 18 º C. (the favorite temperature of different varieties of wheat straw is also different. Here is an example of winter varieties). Therefore, the zoning temperature control system is particularly important. Zoning temperature control at different stages of forage growth can not only promote the good growth of forage, but also increase production.

The environment of low temperature and weak light has a significant impact on the production of wheat straw buds. The environment of low temperature and weak light will affect the normal differentiation of buds and leaves, resulting in poor growth and stagnation in the later stage, or prolonging the seedling age and forming small and old seedlings. After using far-infrared bud cultivation, the above situation can be avoided and the yield and quality of grass seedlings can be significantly improved. The far-infrared band radiated by the warm film is suitable for the growth and development of plants. Therefore, the far-infrared hot film provides an ideal environment for bud cultivation and production.

Led tissue culture seedling supplement light can increase the photosynthesis time of forage, shorten the seedling raising time and growth cycle, and increase the accumulation of organic matter in forage. The programmed band is to control the band of LED light through computer programming. The illumination of different bands has different effects on each stage of forage. Automatic seedling raising can be achieved after computer programming and control.

The spray in the market has two functions: watering and regulation. In the automatic spray system, these two functions are completed automatically without manual inspection. When the seeds or forages need water replenishment, the system will detect and send signals according to sensors such as humidity sensor. After receiving the signal, the spray water replenishment will be activated automatically to spray water for seeds and forages. After reaching the required amount, the control system will automatically adjust to stop spray water replenishment.

The water source recovery system mainly includes three functions: collection, storage and direct utilization after purification. It collects the wastewater from spraying and water replenishment in breeding and irrigation, and transmits it to the water storage place through the pipeline. After being treated by the purification system, it can continue to be transmitted back to the spraying and water replenishment system for continuous use.

After collecting the wastewater from the spray make-up water and irrigation water exchange system, it is filtered, recycled and reused. In this process, some wastewater that can not be recycled will be filtered by the system's safety filtration system and discharged according to relevant regulations.

The hydroponic grass raising system ensures a pollution-free growth environment for forages in the whole process. After the forages grow and mature, the tray automatically takes out the grass through the conveyor belt and can be fed to animals. Since animals eat everything (i.e. roots, leaves and nuts), there is no need to cut grass, and there is no waste in the hydroponic forage system in this process.

Software

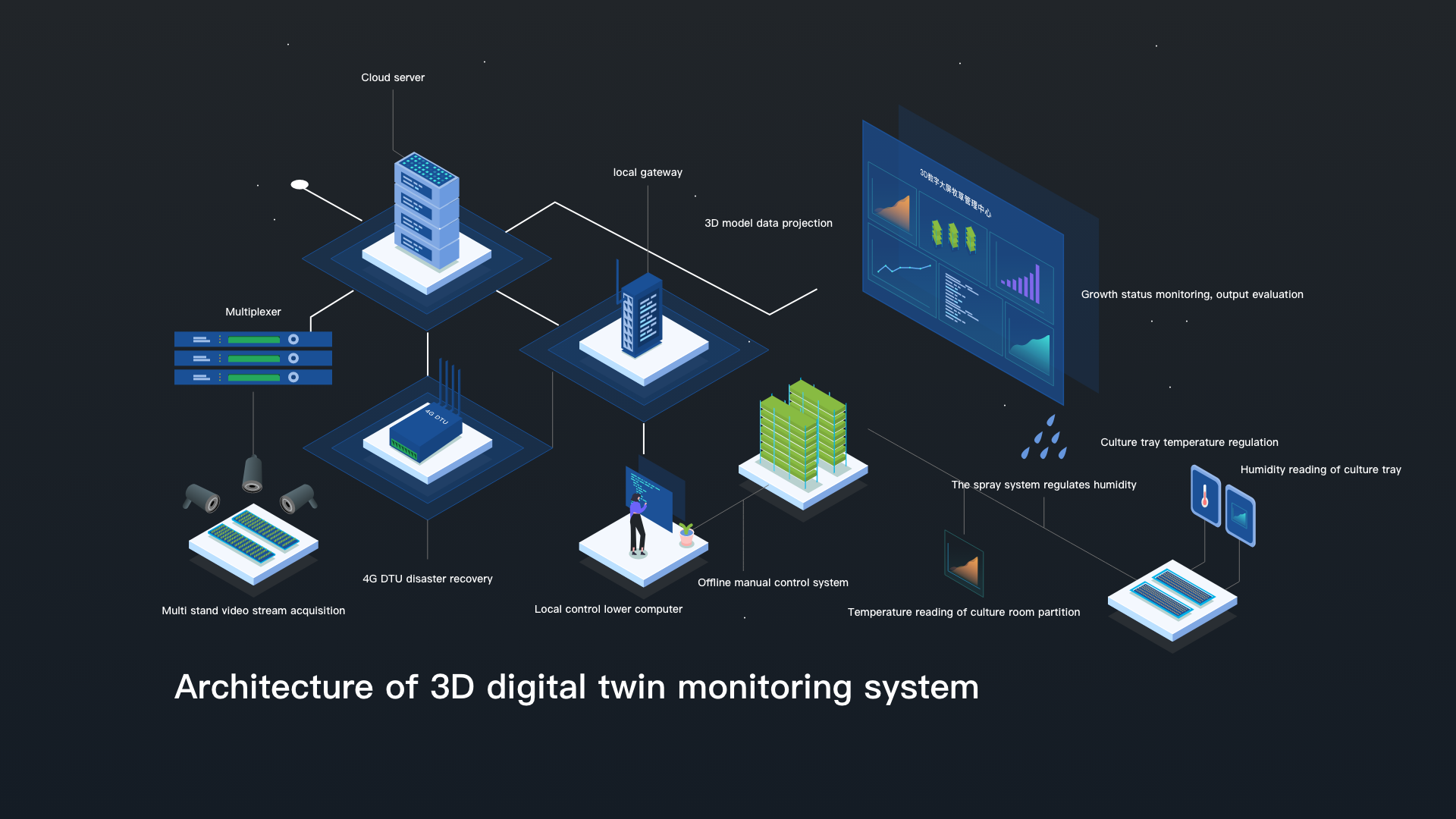

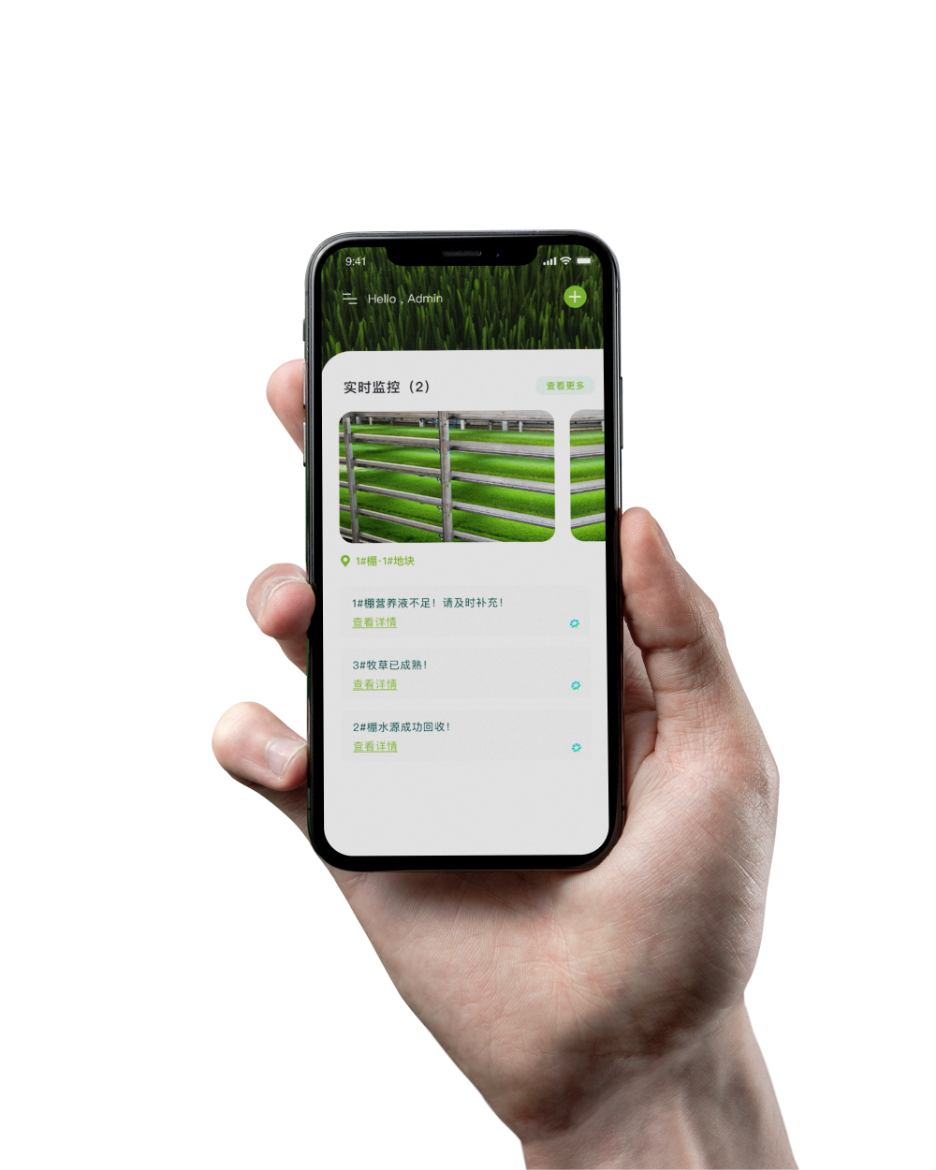

App application display

Master all production information, science and technology, animal husbandry

Multi channel real-time video acquisition

Yield evaluation, 3D data projection

Environmental data collection

Advantages

01 System advantages

· One kilogram of wheat can produce 7-10 kilograms of forage

· The maximum growth rate, 7-day discharge and the combination of water mist culture can further shorten the cultivation cycle

· The indoor growth environment is controllable, the forage has no agricultural residues and high nutritional value, and can be discharged all year round

Advantages

02 System advantages

The indoor pasture will be built nearby without long-distance transportation, and the output can be planned according to demand. It is not limited by geographical location, climate, transportation and other factors. The integration of planting and storage can greatly reduce the excessive production and transportation costs, and can resist the risks of logistics and cold current.

Nutritive value

01 nutritive value

02 nutritive value